Lyocell V-Neck Undershirt

Lyocell V-Neck Undershirt

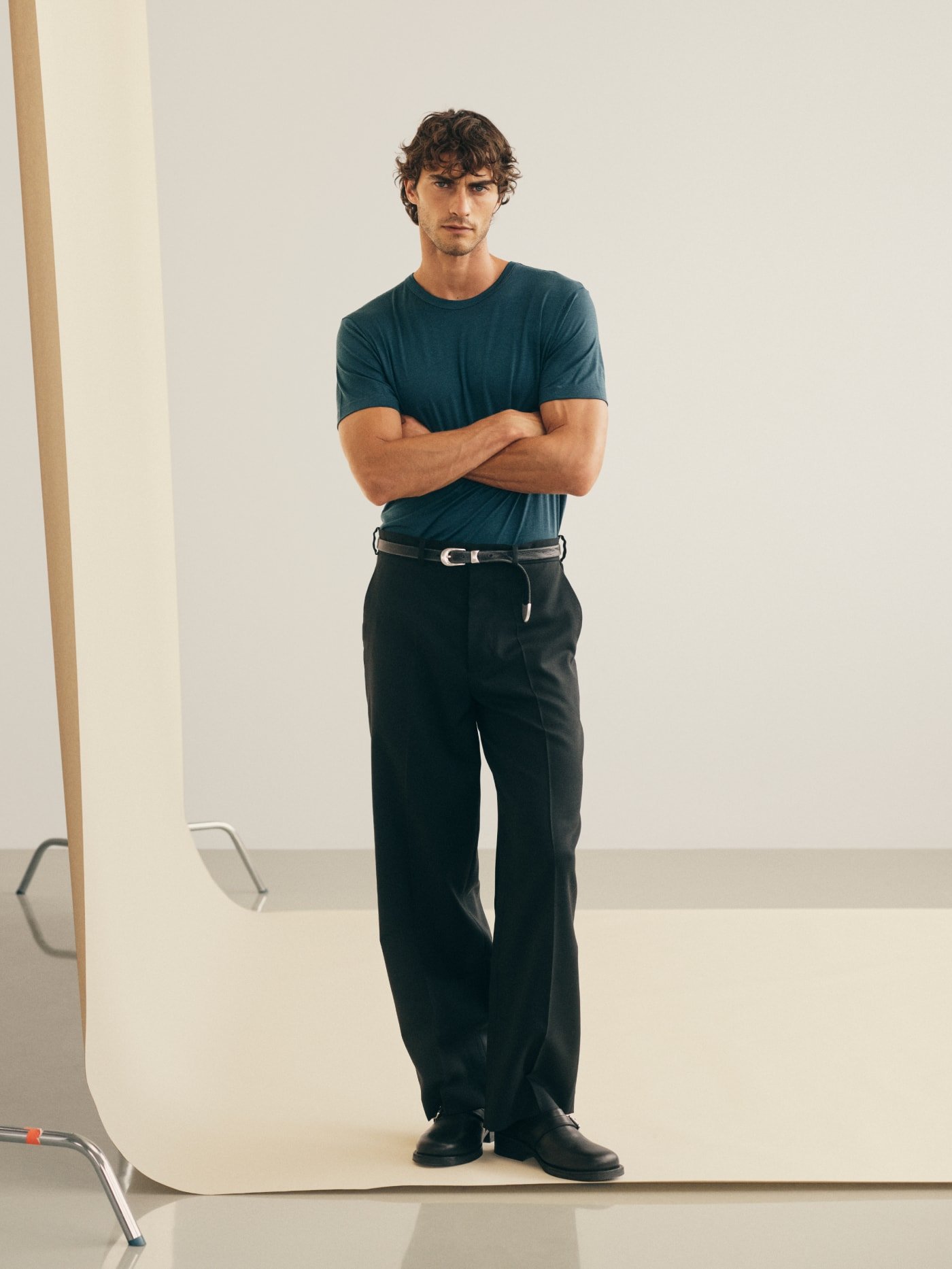

An undershirt engineered to be invisible in color and touch. The range of shades is designed to match your skin tone so visible undershirt lines become a thing of the past.

Made from 100% Lyocell, an innovative cellulosic fiber that’s slightly cool to the touch but also unfavorable to odor-causing bacteria, it keeps you fresh all day. At 150 g/m2, the Lyocell Undershirt feels feather-light on your skin and follows the shape of your body.

Your Lyocell Undershirt is made to order, made to fit, and made to last in Portugal.

Details

LYOCELL UNDERSHIRT

Invisible by design. The Lyocell Undershirt is engineered to disappear under your clothes – in color, feel, and fit. The range of shades is designed to match your skin tone, making visible undershirt lines a thing of the past. Silky against the skin and light as air, it’s a layer that exists to make everything else you wear feel better. Once on, you’ll forget it’s there.

ENGINEERED INVISIBILITY

Made from 100% Lyocell, a cellulosic fiber that’s smooth, breathable, and slightly cool to the touch, keeping you fresh throughout the day.

BARELY THERE

Featherlight construction ensures a second-skin fit that moves with you, staying invisible beneath shirts or knitwear.

SMART PERFORMANCE

Naturally resistant to odor-causing bacteria, Lyocell keeps its freshness longer, even through repeated wear.

Material

Lyocell

Lyocell is one of the most innovative natural fibers in your wardrobe. Made from harvested wood pulp and produced in a closed-loop system that recycles over 99% of water and solvents, it is breathable, soft, and naturally cool against the skin – perfect for warm-weather wear.

Fiber

Fiber Grade

N/AFabric Construction

JerseyFabric Weight

150 g/m2Manufacturing

Production

SON Supply

Our first fully owned factory, SON Supply represents a new chapter for Son of a Tailor – a space where craftsmanship meets control. Based in Santo Tirso, it’s where our Supima T-shirts, sweatshirts, hoodies, and zip hoodies come to life.

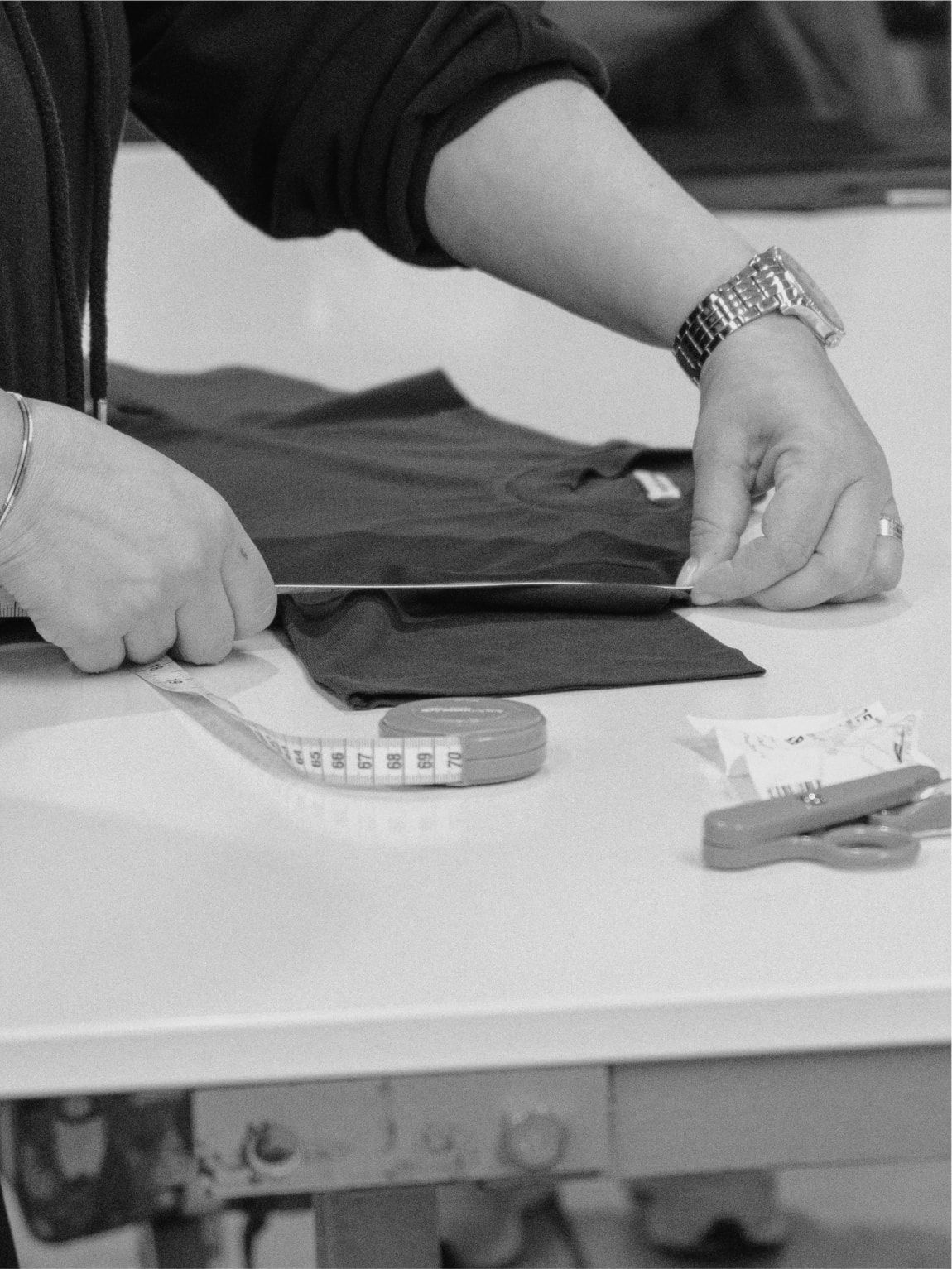

Quality Check

Every Son of a Tailor garment is carefully inspected by hand before it leaves our production floor. Our team checks each piece for fit accuracy, finishing, and overall quality, ensuring you receive exactly what you ordered, and nothing less.

This final step is more than a formality; it’s a promise. By keeping this process in-house, we guarantee every T-shirt, sweater, and hoodie meets the standards we set for ourselves. No shortcuts, no compromises – just honest craftsmanship checked by the same people who made it.

Shipped Directly

Unlike most clothing brands, we manage not only our production but also our logistics, meaning your garments travel as quickly as possible from our hands to yours.

By handling fulfilment internally, we eliminate unnecessary middlemen and reduce errors. The result is a simpler, faster, and more reliable process – one that mirrors the precision of how our products are made. It’s a small detail that makes a big difference in ensuring every order arrives exactly as intended.

End to end Production

In 2022, we established SON Supply, our own production facility in Santo Tirso, Portugal. Today, over 55% of our garments are made there, with the rest produced by a tightly knit community of trusted artisans across the country.

Together, they share our commitment to quality, precision, and sustainability. From cutting to knitting, sewing to packaging, every step happens under our supervision. We take pride in doing the hard work ourselves – creating products made for you, made to order, and made to last. This is what end-to-end craftsmanship looks like.

Service

Whether you’re ordering your first T-shirt or you’ve been with us for years, we take the time to make sure you get exactly what you need. If something isn’t right, we fix it. Our team is easy to reach and empowered to help.