Lyocell T-Shirt

Lyocell T-Shirt

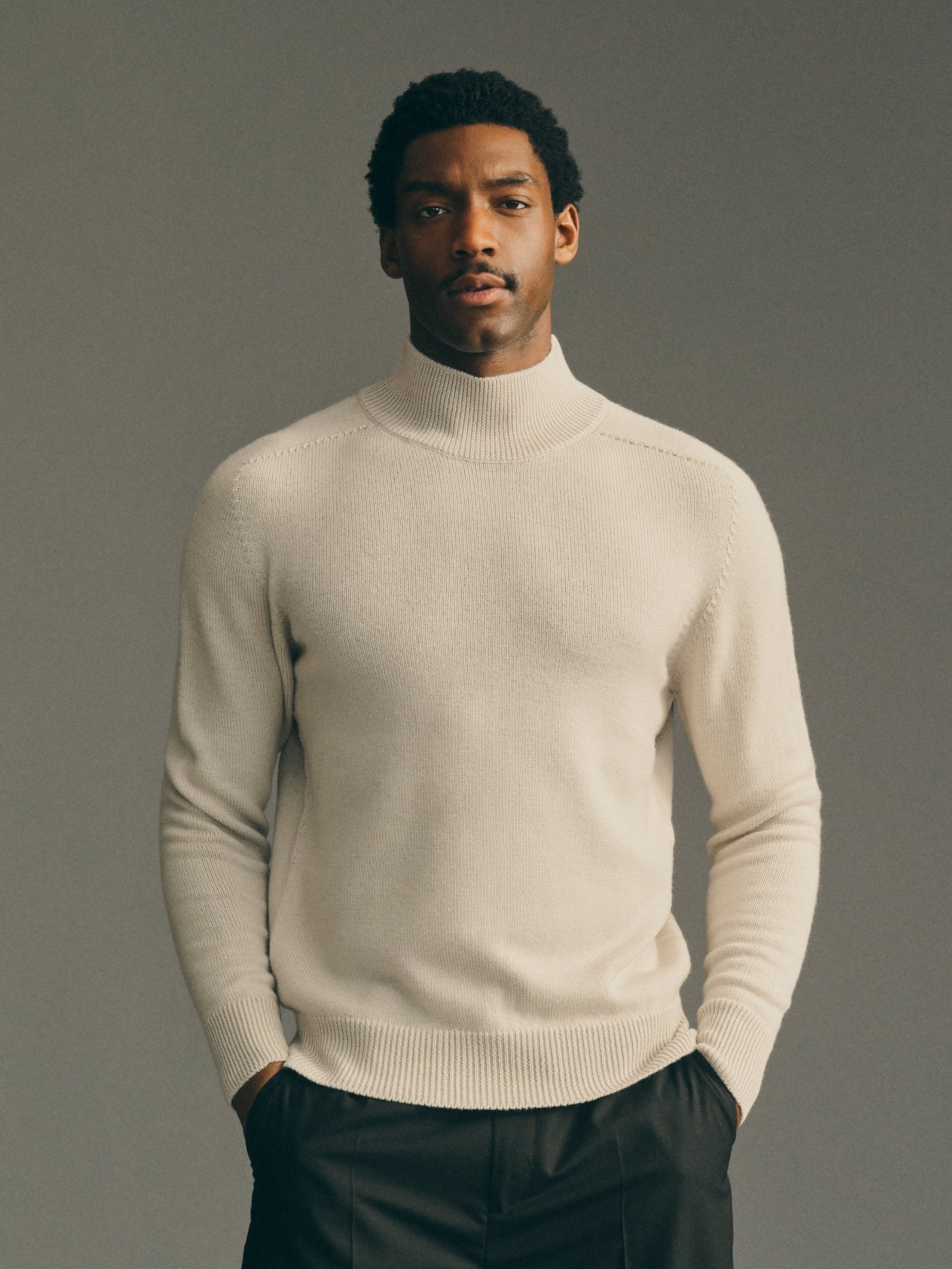

Soft as silk, this is a T-shirt like no other. The secret sauce? Lyocell, an innovative cellulosic fiber derived from certified and controlled trees.

Lyocell is a true powerhouse. Not only is it smooth and slightly cool to the touch but also unfavorable to odor-causing bacteria, keeping you fresh on hot days. We blend it with organic cotton for extra strength and a subtle melange look. At 170 g/m2, the Lyocell T-Shirt feels light and has an airy drape.

Your Lyocell T-Shirt is made to order, made to fit, and made to last in Portugal.

Details

LYOCELL T-SHIRT

A study in softness and innovation. The Lyocell T-Shirt is made from lyocell – a cellulose fiber spun from wood pulp in a closed-loop process that recycles over 99% of water and solvent. The result is a fabric that feels luxuriously smooth, naturally breathable, and cool to the touch, offering comfort that’s as considered as it is refined.

UNIQUE MATERIAL

A blend of 67% lyocell and 33% organic cotton – combining the silk-like smoothness of lyocell with the familiarity and structure of cotton.

EFFORTLESS DRAPE

Cut for movement and ease, it follows the body without clinging, balancing softness with structure for an unmistakably modern silhouette.

COOL PRECISION

Lyocell’s natural moisture management keeps the fabric cool and dry, while its gentle sheen gives the T-shirt a quietly refined finish.

Material

Lyocell

Lyocell is one of the most innovative natural fibers in your wardrobe. Made from harvested wood pulp and produced in a closed-loop system that recycles over 99% of water and solvents, it is breathable, soft, and naturally cool against the skin – perfect for warm-weather wear.

Fiber

Fiber Grade

N/AFabric Construction

JerseyFabric Weight

170 g/m2Manufacturing

Production

Poltex

Our first-ever supplier and one of our most trusted partners. Poltex, in Guimarães, helped turn the Son of a Tailor vision into reality – producing our polos, Tencel tees, and piqué shirts with craftsmanship and care that have stood the test of time.

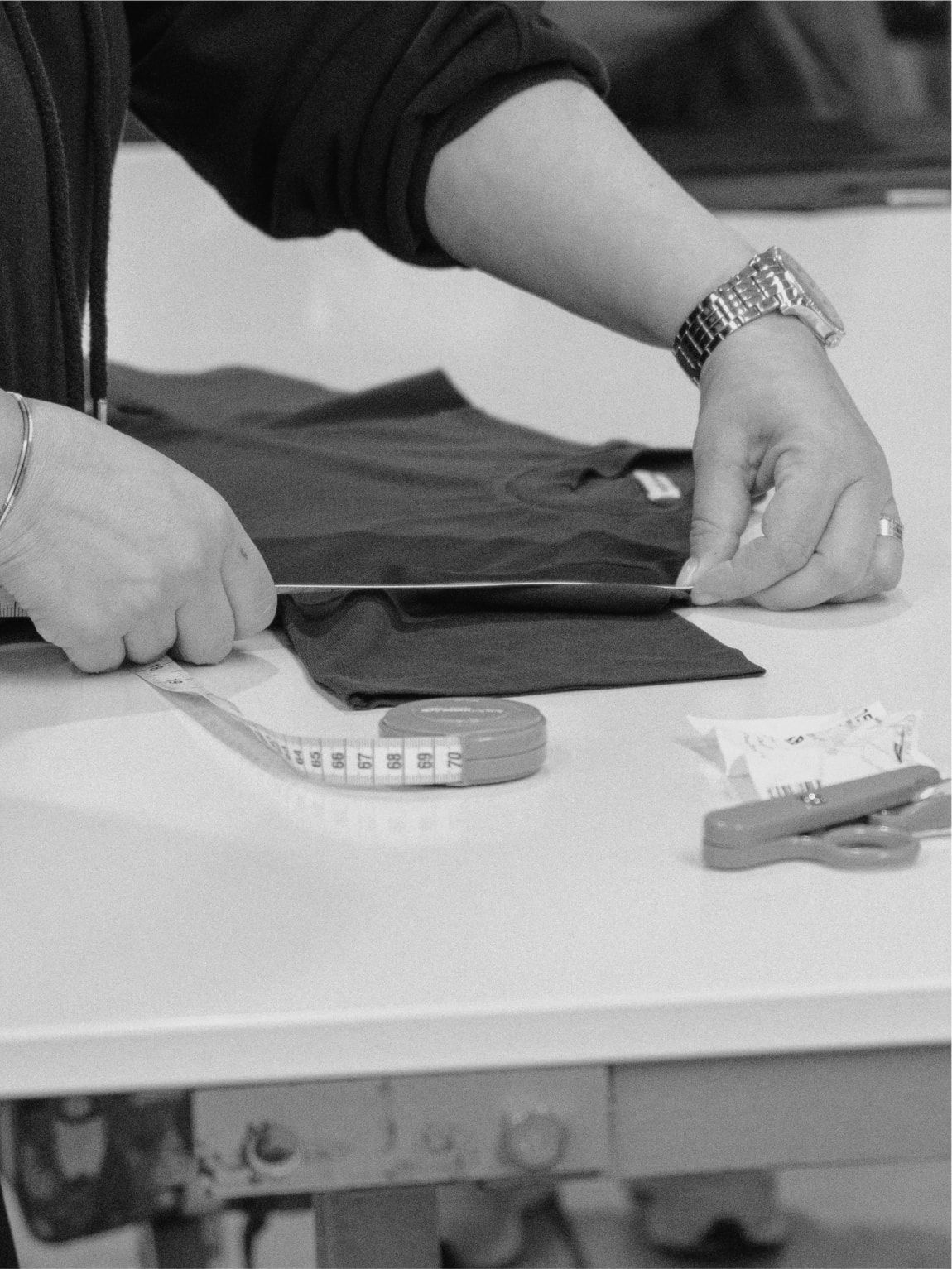

Quality Check

Every Son of a Tailor garment is carefully inspected by hand before it leaves our production floor. Our team checks each piece for fit accuracy, finishing, and overall quality, ensuring you receive exactly what you ordered, and nothing less.

Shipped Directly

Unlike most clothing brands, we manage not only our production but also our logistics, meaning your garments travel as quickly as possible from our hands to yours.

End to end Production

In 2022, we established SON Supply, our own production facility in Santo Tirso, Portugal. Today, over 55% of our garments are made there, with the rest produced by a tightly knit community of trusted artisans across the country.

Service

Whether you’re ordering your first T-shirt or you’ve been with us for years, we take the time to make sure you get exactly what you need. If something isn’t right, we fix it. Our team is easy to reach and empowered to help.