Field Notes #5

The process of making with Warren Martin

Dubbed ‘Steel City,’ the town of Sheffield bears remnants of its industrial past and present everywhere. But look closer and that work becomes rarer, the kind that lives in muscle memory, preserved by those who pass it on hand to hand.

For this installment of Field Notes - our series exploring the inspiring lives of people shaping culture through craft, creativity, and care - we spoke to Warren Martin, one of the last silver spinners in the UK and a guardian of the craft’s future.

We met him in his workshop, tucked away in an attic in Sheffield’s industrial quarter. Tools of every size and shape cover all of its surfaces, most of them older than any of us in the room, still used to give raw material its form. Watching the work up close offers a rare view not just into the craft of silver spinning, but it begs the question: how might our relationship with the objects around us change if we understood more about the process, and the people behind it?

“In silver spinning, a flat disc of metal becomes the foundation everything else depends on. Get it right, and the work can move forward. Get it wrong, and there’s no undoing it.”

Warren is wearing the Extra Heavy Cotton T-Shirt.

The hands behind the craft

Watching his dad work with metal, Warren learned early what it meant to make something using your own hands. “He insisted that I get myself a trade,” Warren tells us. “Except I wanted to go to art college and do something creative.” Silver spinning is where those instincts met: a craft rooted in skill and repetition, yet rarely recognized as the foundation of how things are made. That starting point is what draws him to the work.

In the workshop, we watch Warren pick up the disc of metal and set it against the lathe. As the lathe spins, he leans in, bracing his body, guiding the metal with steady pressure. The physicality of silver spinning is astounding. A few minutes later, he steps back and holds a small bowl in his hands. In that moment, the object no longer feels separate from the hands that produced it.

In Warren’s field, the work is never the result of one pair of hands. A single piece of silverware can pass through eight or nine craftspeople, yet most go uncredited. In precious metals, the mark usually belongs to the sponsor, not the maker. For Warren, the person behind the work matters as much as the work itself. It’s the maker who defines the quality.

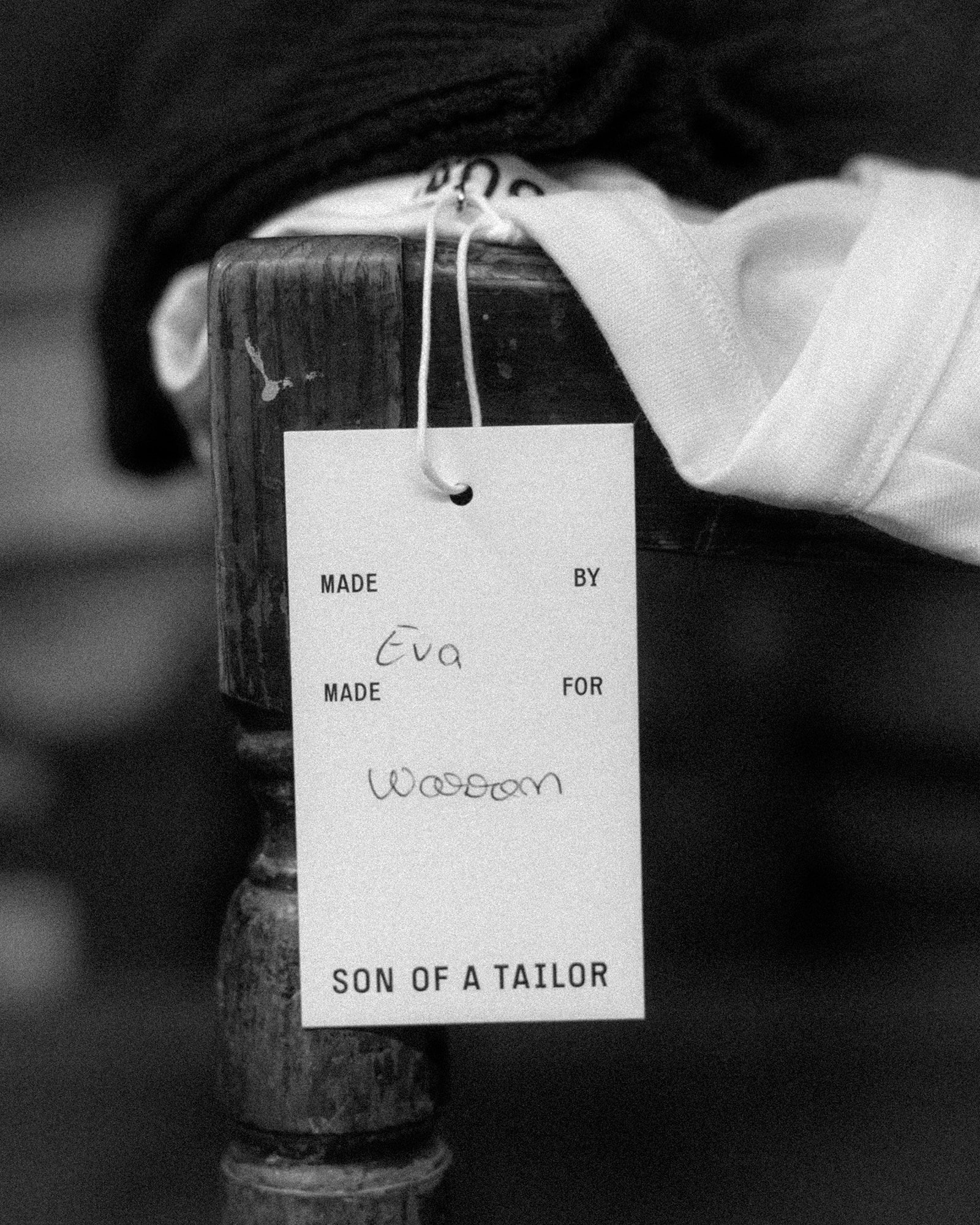

“I think it’s a really nice touch with Son of a Tailor clothing that the label carries the name of the person who made it. It tells you there’s a human hand involved.”

The future of making

Watching Warren work, it becomes clear that silver spinning is difficult to do well. The challenge isn’t learning the technique, but being able to repeat it consistently, at speed, without compromising the material or the form. Warren is among the last generation trained to do so. In the UK, he’s one of only two silver spinners under the age of 50, and the craft itself is now considered critically endangered.

When he speaks about being one of the last, the weight shows in his voice. But he doesn’t give in to despair.

“People have sort of lost the idea of what quality is. And I do think we're returning to that.”

Much of Warren's work is still misunderstood as mechanical, when in reality every piece is shaped by his own hands. "The only thing the lathe is doing is rotating," he explains, “in the same way that a potter's wheel rotates. But no one ever thinks of pottery as a mechanical process. I'm a potter that works in metal.”

For Warren, understanding how something is made fundamentally changes its meaning. When he looks at silverware, he doesn't see the finished object. He sees the craftspeople who touched it, hands from hundreds of years ago. "It's not the materialism of the piece itself," he says. "It's the hands and the skill that went into making it.”

That perspective is something he hopes more people will discover. When you understand the process, you ask better questions, look longer, keep things longer. Quality becomes something you recognize. What he wants to pass on isn't just the technique of silver spinning, but a renewed commitment to skill, to process, and to the value that lives in the hands behind what's made.

Folded on a stool are the Winter Wool T-Shirt and the Heavy Merino Sweater.

Further Reading

Made for... Georg

Vienna-based creator Georg on vintage, quality, and the quiet beauty of considered style.