Cotton / Re-Spun

From waste to possibility

At Son of a Tailor, reducing waste isn’t a limitation, it’s an opportunity. Our made-to-order model already minimizes overproduction by crafting each garment precisely for you. With Re-Spun, we went even further, asking:

What happens when we look at what is left, not as waste, but as possibility?

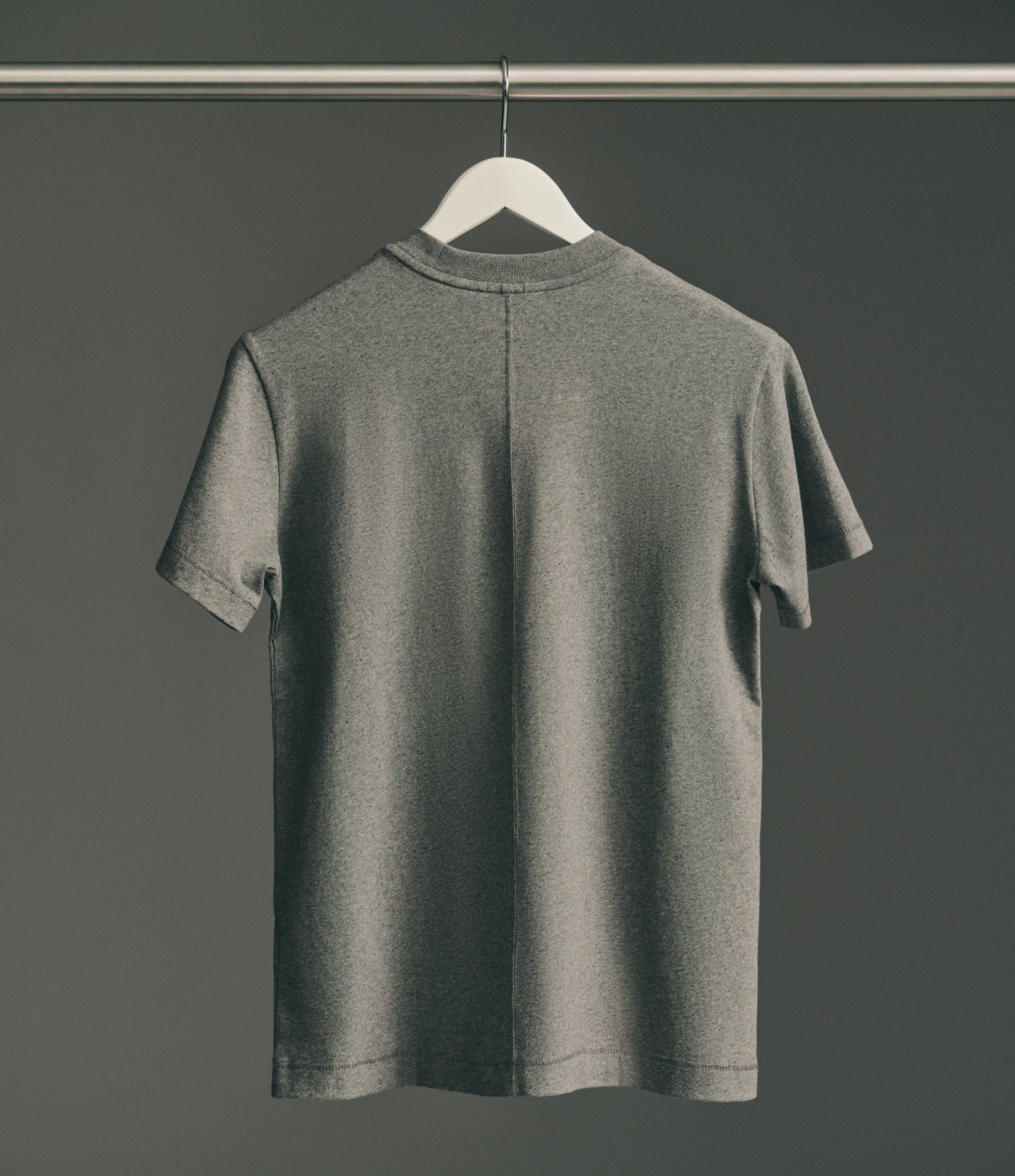

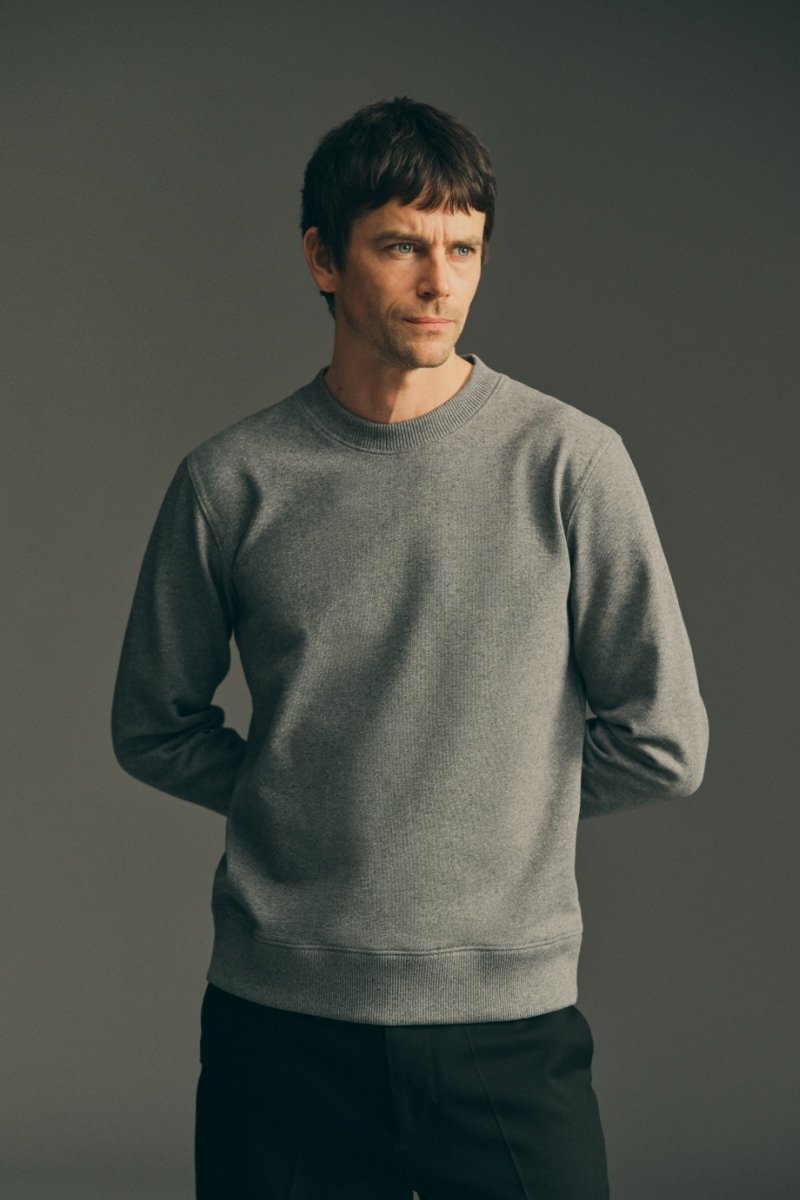

We took this mindset and transformed cutting waste into durable, high-quality garments: the Cotton T-Shirt / Re-Spun and Cotton Sweatshirt / Re-Spun prove not only that this is possible, but they also turn the recycling process into a visible design feature.

Built for what’s coming, not just what’s required

Even in made to order production, cutting waste is inevitable. With the Re-Spun initiative, we take responsibility for that waste by transforming it back into yarn instead of passing it along. In doing so, we move closer to true circularity by producing garments made with 50 percent recycled Supima cotton from our own supply chain, while exploring new processes and expanding our supplier network.

Re-Spun also aligns with emerging EU Ecodesign requirements that emphasize reusability and sustainable material cycles, and by acting now we prepare our products and operations to meet these evolving standards responsibly, reinforcing our commitment to transparency, accountability, and continuous improvement.

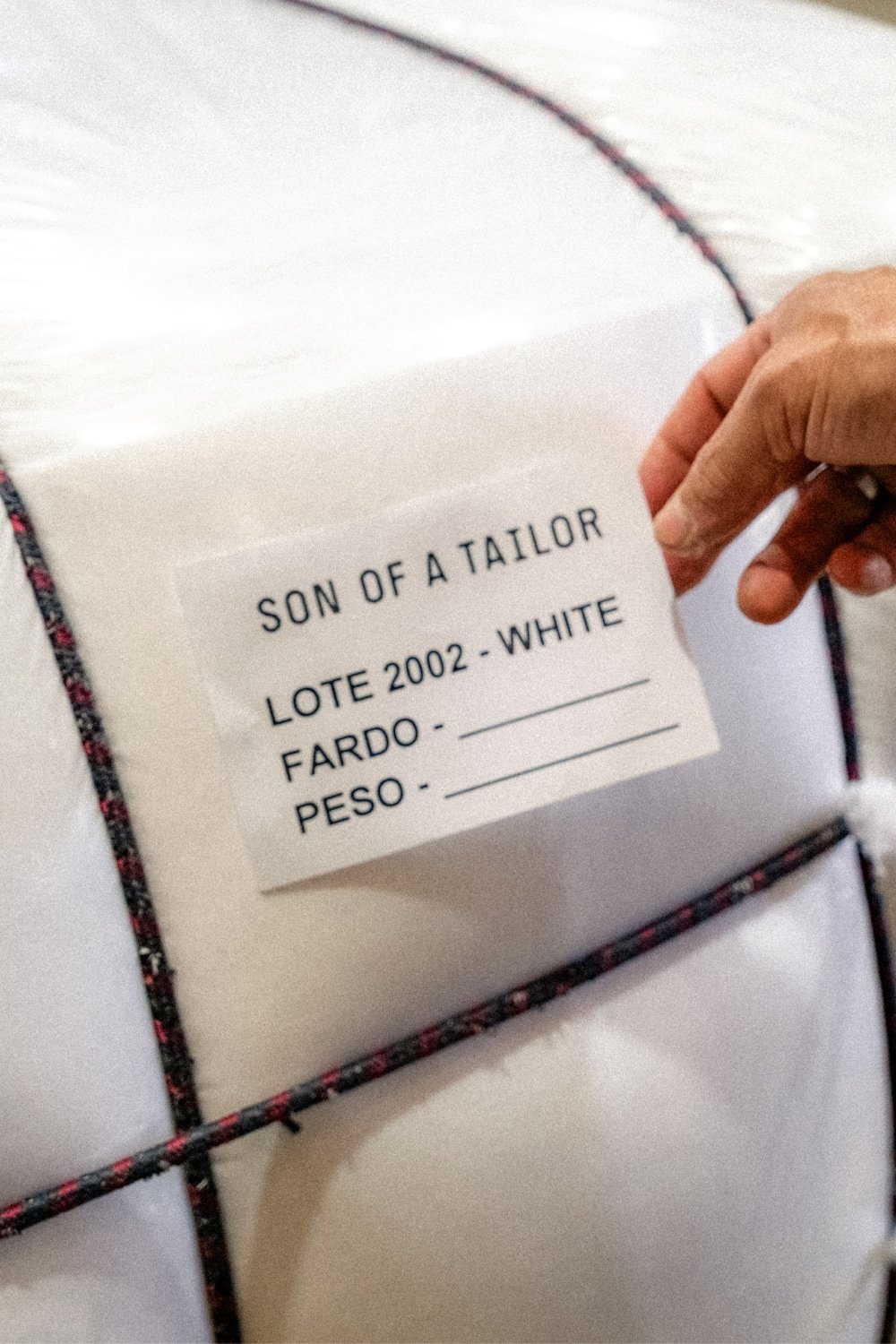

“Ironically, the main challenge of this project was collecting enough cutting waste to meet the minimums of the shredding machines at our partner Recutex. It took nearly a year to gather enough material to get started.”

But, how do we get from cutting waste to the final garment?

Each T-shirt consists of five pattern pieces. These pieces are arranged to use the fabric as efficiently as possible. Still, because of their shapes, some leftover fabric scraps are unavoidable. Rather than treating this as waste, we chose to see it as raw material. Over the course of nearly a year, we collected cutting waste from our Supima Cotton T-Shirt production and transformed it into two entirely new garments.

1. From waste to fiber

Once sufficient material had been gathered, the cutting waste was sent to our partner responsible for fiber shredding - Recutex. They’re a family business specialized in textile-recovery: transforming cutting waste into high-quality recycled fiber.

At Recutex, the cutting waste is cut and broken down into smaller pieces, then combed until it returns to fine fibers. When the fibers reach the required quality, they are compressed into bales and transported to the spinning mill.

2. From fiber to yarn

At Inovafil, our spinning partner specializing in innovative, high-quality yarns, the recycled fibers are blended and twisted with virgin organic cotton and spun into a 50/50 composition. This balance is essential, as recycled fibers shorten during shredding and cannot provide strength on their own.

The finished yarn is then wound onto cones, ready for knitting.

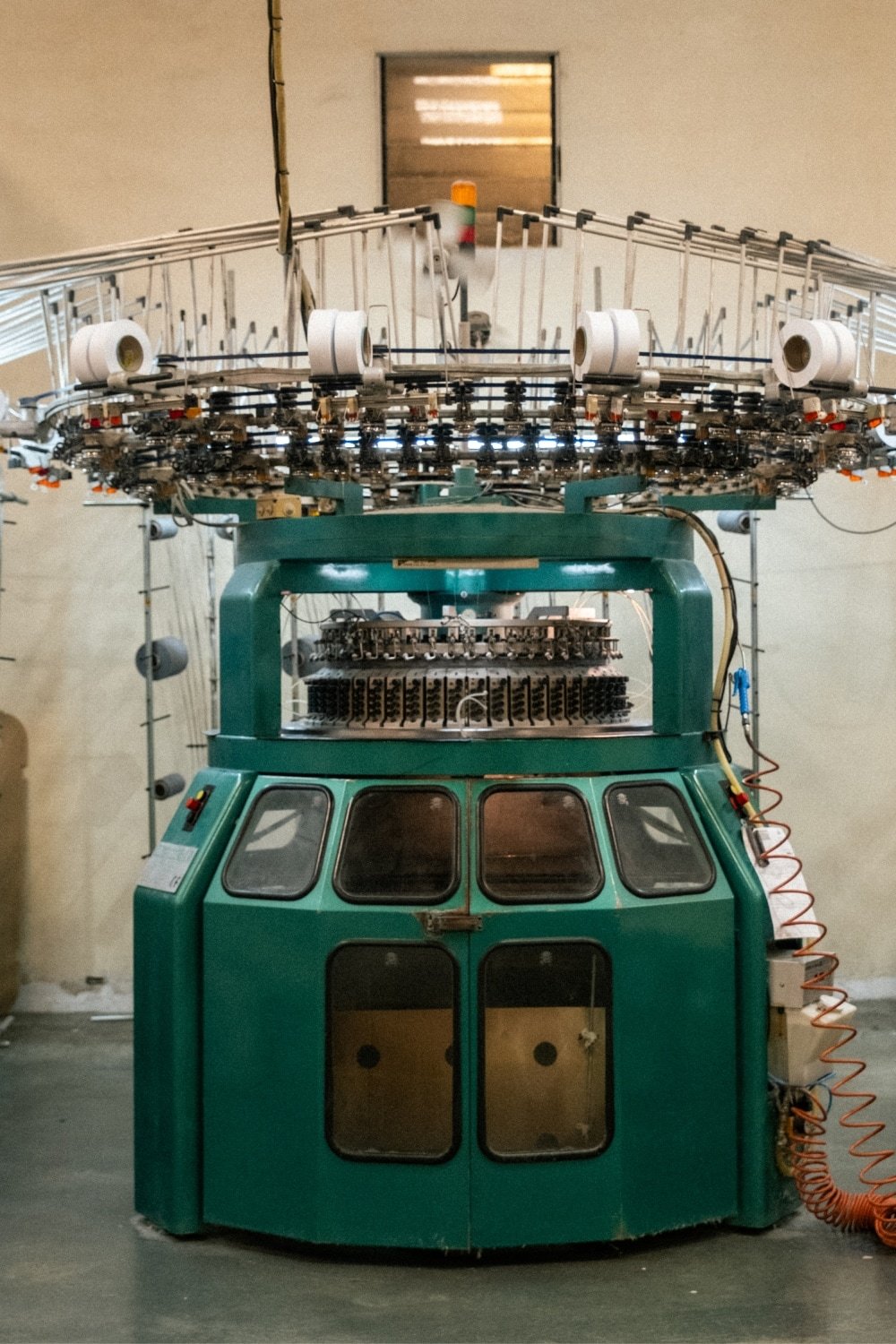

3. From yarn to fabric

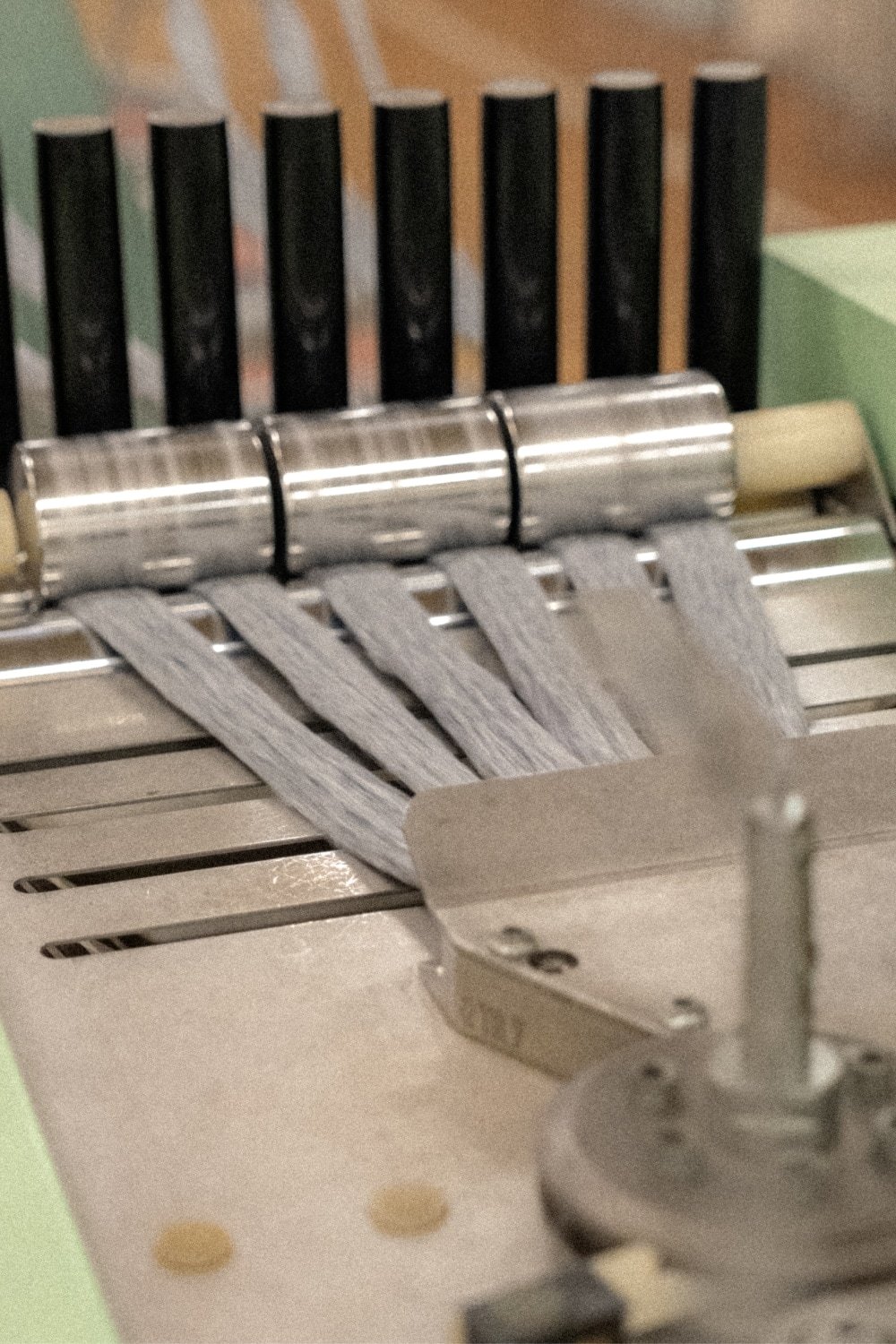

The yarn cones are sent to NGS, our knitting and finishing partner, where they are transformed into two fabrics using a gauge-20 machine: a 200g jersey with a 2×2 rib and a 410g fleece with a 2×2 rib. Both are made from recycled yarn spun at Inovafil, with 2% elastane added to the rib for elasticity and shape retention.

No dyeing is needed. The final color comes directly from the fiber blend of 25% black Supima cotton waste, 25% white Supima cotton waste, and 50% white organic cotton. The fabric only requires washing and a soft anti-peeling finish, significantly reducing water and energy use.

4. From fabric to garment

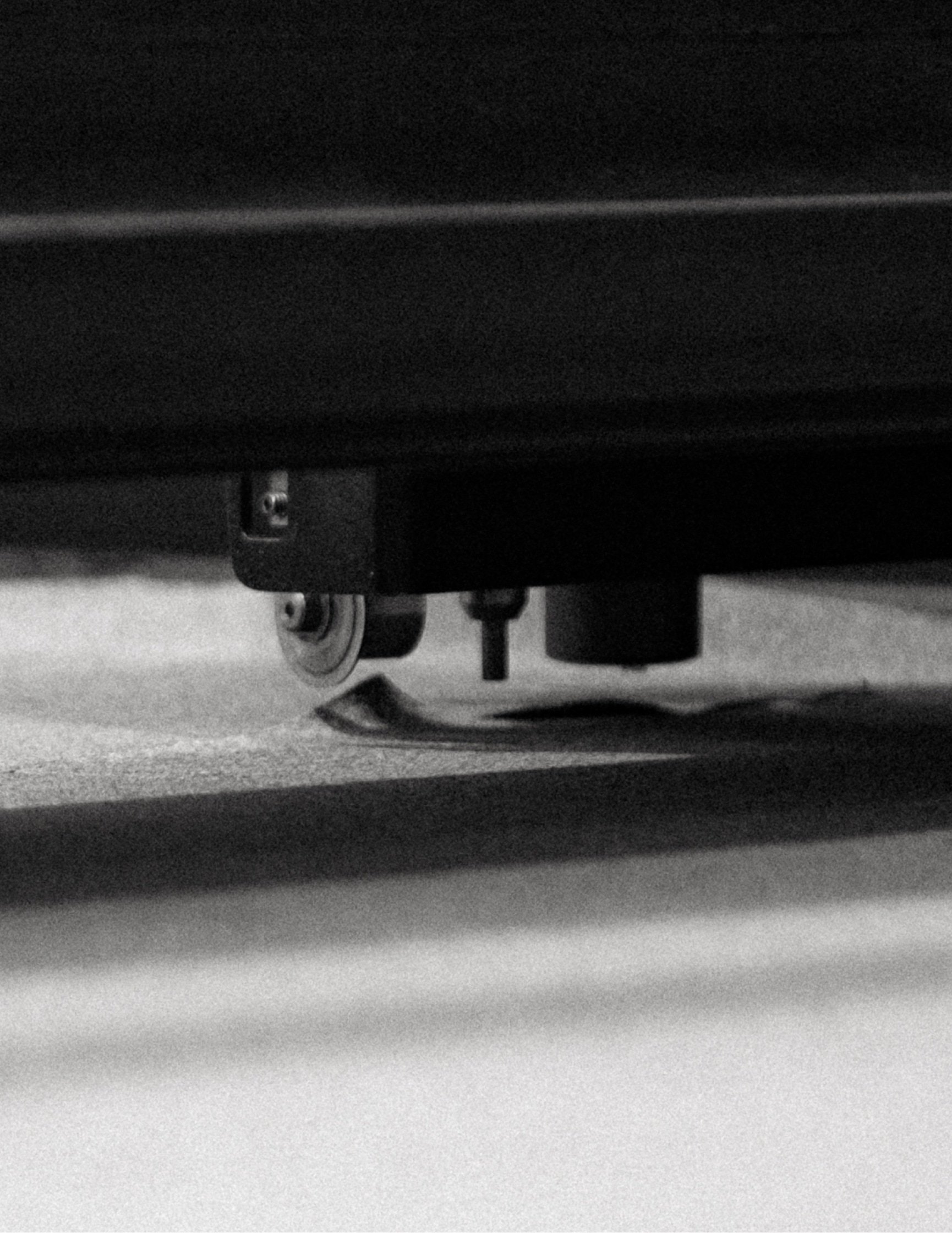

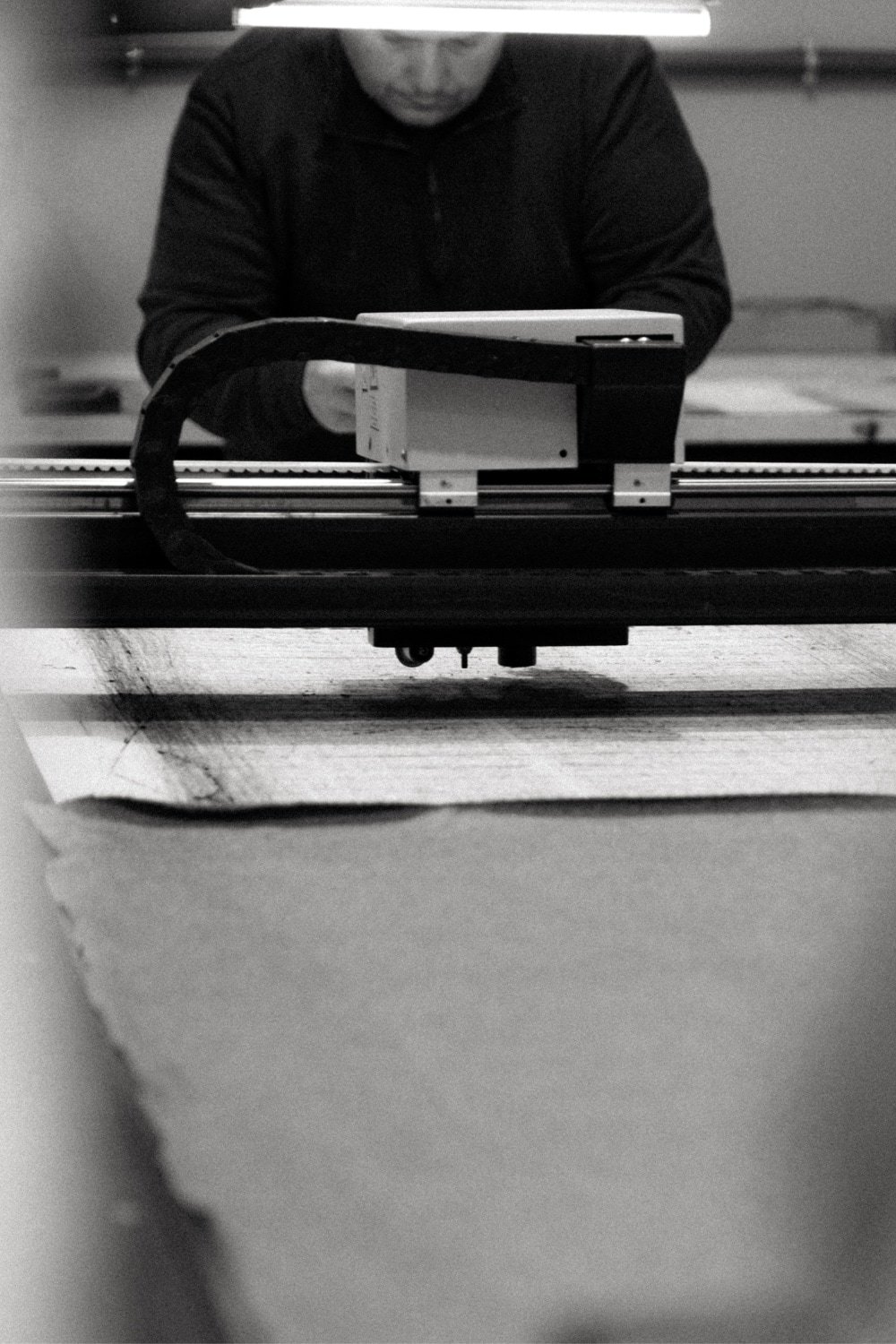

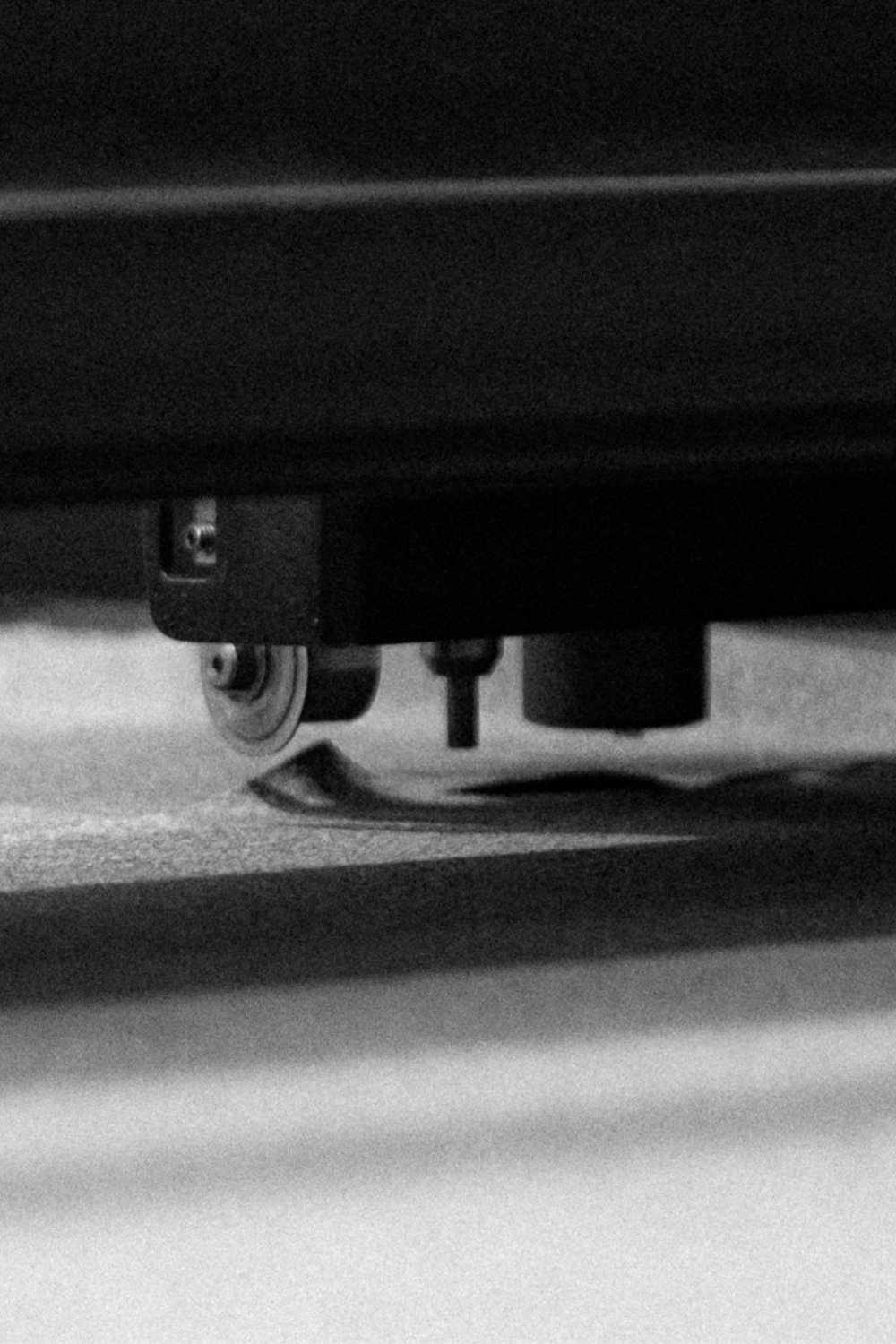

The finished fabric is sent to our production facility, SON Supply, where each garment is made to order. When you place an order, a unique pattern is automatically generated to your measurements and sent to our cutting machine.

The fabric is cut in a single layer, and the pieces are assembled by our seamstresses with care and precision. The garment is then washed, pressed, quality-checked, packed in a biodegradable bag, and prepared for shipment from our fulfillment center.

The end result is two elevated essentials, a T-shirt and a Sweatshirt, whose design is directly inspired and informed by the recycling process itself. Rather than hiding the journey from waste to new yarn, we chose to let it shape the outcome, allowing the material’s origin and transformation to influence both construction and expression.

By blending 25% recycled black Supima cotton with 25% recycled white Supima cotton and 50% white organic cotton, we created a distinctive melange colorway that represents its composition, Re-Spun Grey. The seam detail on the back came from optimizing how the pattern is cut to reduce waste, again reflecting the production process and turning it into a design feature.

The final fabric is composed of 50% recycled Supima cotton from our own production waste and 50% organic cotton. Supima cotton’s extra-long staples ensure supreme quality even after recycling.