The making of cashmere

Our partnership with Linsieme, Italy’s master spinners

This October, we introduced our first cashmere collection, a milestone made possible through our partnership with cashmere spinning house Linsieme, one of Italy’s leading cashmere spinners. Founded in the early 1980s and based in Prato, just an hour north of Florence, Linsieme has built its reputation on a rare balance of tradition, innovation, and care.

We spoke with Stefano Nesi, the founder, about the origins of Linsieme, the art of spinning fine fibers, and what makes this collaboration special.

What inspired you to start a cashmere spinning facility in the 1980s?

Linsieme was born in the early 1980s from a deep passion and genuine love for fine fibers. From the start, our goal was to highlight the excellence of natural materials – especially cashmere – by creating yarns that blend artisanal quality with technical innovation.

At the time, interest in noble fibers was growing in Italy, but the cashmere supply chain was still in its infancy. We saw an opportunity to do something unique: to build a spinning mill dedicated entirely to cashmere, combining respect for Italian textile tradition with a forward-thinking vision focused on quality and sustainability.

What makes Italy such a special place for producing cashmere yarn?

Italy has long been synonymous with excellence in fashion and design. It’s home to iconic designers and a deeply rooted culture of quality and craftsmanship.

In cashmere production especially, Italy stands out thanks to its unique combination of artisanal know-how, cutting-edge technology, and refined aesthetic sensibility. Here, attention to detail is not just technical – it’s cultural. This environment of passion, skill, and taste makes Italy an irreplaceable place for working with such precious fibers.

How would you describe what sets Linsieme apart in the industry?

What truly sets Linsieme apart is our balance of tradition and innovation. For over forty years, we've pursued our craft with the same passion as day one – always with an eye on the future. Every step of our production – from raw fiber selection to final spinning – is handled with extreme care, in a tailor-made approach that prioritizes lasting quality.

We’re an independent, people-first company where every decision is driven by a commitment to excellence. We’re most proud of the trusted relationships we’ve built over time – both with small-scale fiber producers who share our values, and with customers who come to us for our consistency, reliability, and craftsmanship.

Mr Nesi and the Linsieme team winning The Santo Stefano Award for innovation and entrepreneurial excellence

“In an industry increasingly focused on quantity, we continue to believe in quality. That’s the heart of Linsieme.”

In your view, what makes cashmere a unique material?

Cashmere is an extraordinary fiber, born under exceptional conditions. It comes from the Capra Hircus goat, which lives at altitudes of 3,000–4,000 meters in regions like Mongolia and Tibet. This is why it’s often called “the fiber closest to God” – a poetic way of expressing both its elevated origin, and its rare qualities.

The most precious part is the undercoat: an ultra-fine, incredibly soft layer that protects the animal from extreme cold. From this, we obtain a yarn with unmatched qualities: warm yet light, soft to the touch, elegant and refined.

What are the main challenges involved in spinning high-quality cashmere yarn?

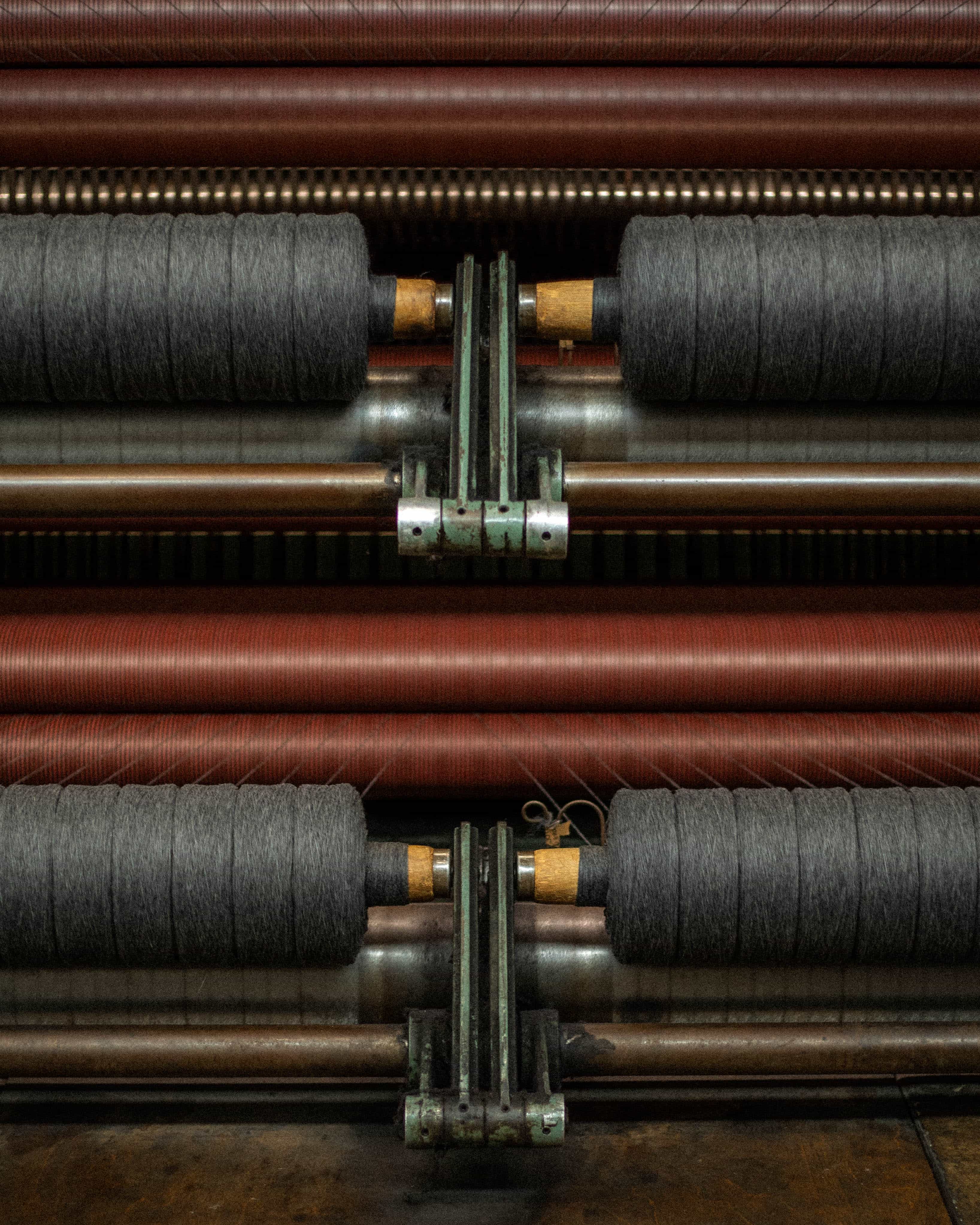

Spinning cashmere is both an art and a challenge. It’s a noble yet delicate fiber, and preserving its softness, lightness, and natural fineness takes great care.

It requires high-performance machinery that can handle the fiber gently, but also deep expertise and attention to every step of the process. Nothing can be left to chance. High-quality cashmere spinning is about finding the right balance every day – between technology and the artisan’s hand, between innovation and respect for the fiber’s nature.

It’s a demanding job, but that’s exactly what makes it so rewarding.

What excites you most about your collaboration with Son of a Tailor?

Our shared vision: a thoughtful, quality-first approach rooted in care and responsibility. For the product, the people, and the planet. Seeing our cashmere transformed into such well-crafted garments – designed to last and to truly accompany those who wear them is a great source of pride.

It’s a pleasure to work with a brand that doesn’t chase trends, but stands for authenticity, sustainability, and timeless beauty.

“Cashmere is more than a raw material – it’s an experience.”

Find out more about Stefano Nesi and Linisieme on the company website, and check out our limited Cashmere Collection.