Son Supply

A peek at our Portuguese production facility.

Since day one at Son of a Tailor, we’ve believed that precision and craftsmanship should go hand in hand with textile production. In 2022, we took a major step toward realizing that vision by launching SON Supply, our very own production facility, when we joined forces with local production manager Sr. Sousa. He and his team remained in place, working exclusively on Son of a Tailor garments under the SON Supply umbrella.

This wasn’t just a business move. It was a commitment to quality, efficiency, and responsible manufacturing. Today, SON Supply produces approximately 60% of our orders (and we’re working on the rest), ensuring greater control over every stitch, seam, and finish.

The exception, not the rule

Owning a production facility is a rarity in the fashion industry. Most brands outsource production, distancing themselves from the ethical and environmental implications of their supply chain. We aimed to disrupt this model. By bringing production in-house, we ensure fair wages, safe working conditions, and transparent processes, from the initial cut to the final stitch.

Inside SON Supply

The sound of sewing machines hums steadily as Maria carefully stitches the final seam on a custom-fit T-shirt. She’s been with us since the beginning of SON Supply, bringing decades of expertise to every garment she crafts. Put simply, it’s different here. We’re not just making clothes – we’re making clothes for someone specific. We see their name, their order, their measurements and preferred size, and then we get to work.

Unlike traditional production facilities churning out thousands of identical pieces, SON Supply operates at a different pace – one that prioritizes craftsmanship over speed. Each order is measured, cut, sewn, and finished by skilled artisans who take pride in their work.

Son Supply / Portugal.

Nestled just outside the historic city of Guimarães in northern Portugal, SON Supply is home to a dedicated team of over 20 skilled seamstresses and artisans. Under the experienced leadership of Production Manager Mr. Sousa, the team has recently implemented enhanced quality control measures, refined pattern-cutting techniques, and assumed full ownership of shipping logistics.

Beyond strict compliance with the labor laws of the European Union, SON Supply (along with our carefully selected external partners) upholds all principles of the International Labour Organization (ILO), including collective bargaining rights, the prohibition of forced and child labor, and a steadfast commitment to fair wages.

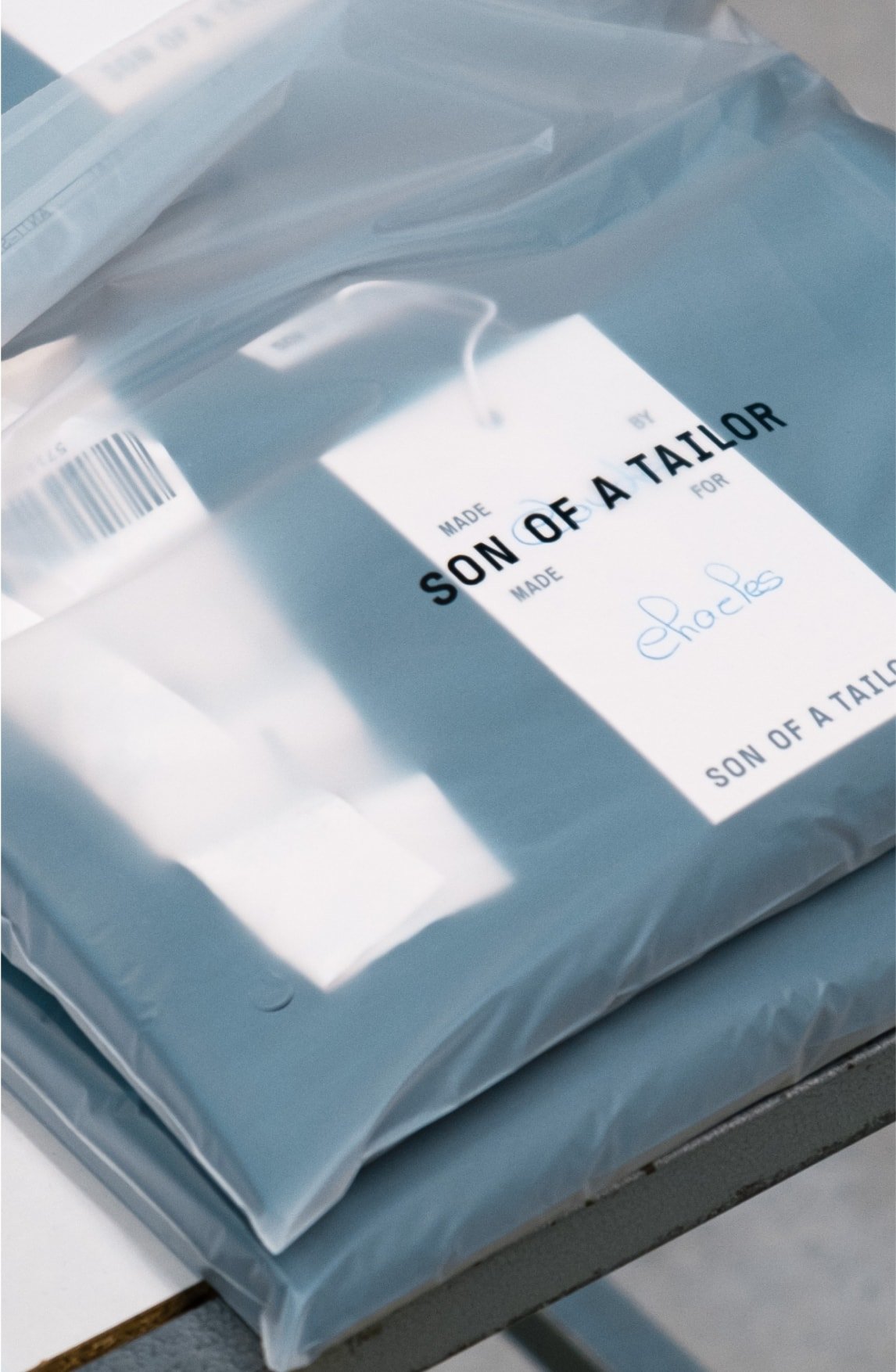

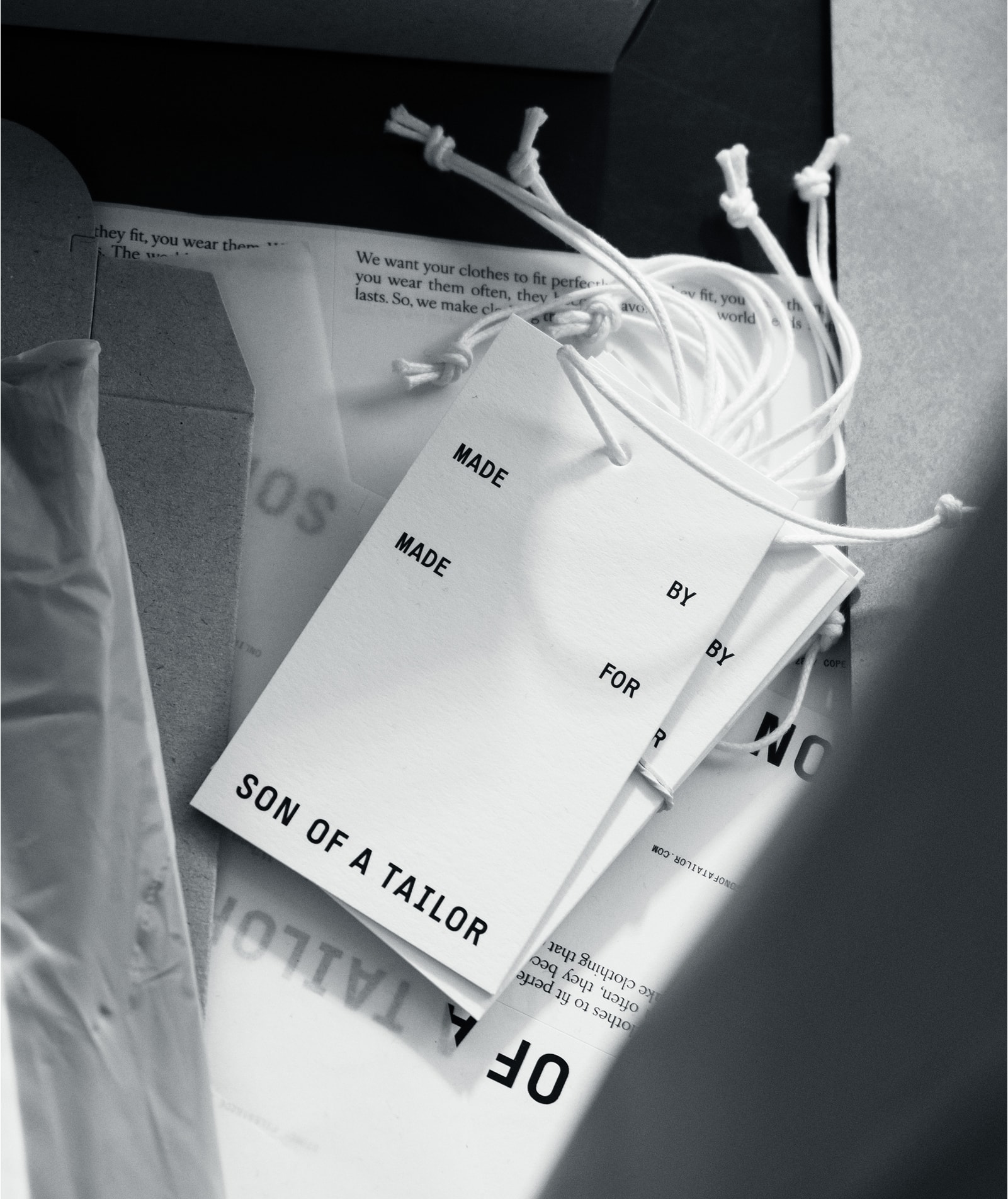

There’s also the personal touch. Having our own production facility and running our own logistical effort means we can build a subtle connection between our customers and the people making their garments. Every Son of a Tailor product comes with a handwritten name tag: Made for X, Made by Y. It might be a small, incidental detail for some, but for us, it represents our approach to quality, craftsmanship, and customer service.

What all this means for you

If you’ve ever ordered from Son of a Tailor before, you might have noticed something: your fit keeps getting better. That’s because owning our production facility means we can fine-tune every aspect of how our garments are made – ensuring consistency in sizing, improving fabric precision, and making small adjustments based on customer feedback. In fact, since launching SON Supply, we’ve reduced our order-to-delivery time by 26% on all T-Shirts – and we are consistently trying to up our game here.

Beyond speed, we’ve seen other customer benefits since introducing SON Supply:

Every cut, every stitch, every fabric offcut – we account for all of it. At SON Supply, we’re not just reducing waste; we’re constantly trying to optimise our supply chain and, in some small way, be part of transforming the fashion production industry.

So, what’s next? Hitting the one million products sold milestone last year made us realize that, even though we’re cutting waste to a minimum, perhaps there’s something still to be done with our fabric offcuts. Therefore, we’ve kicked off a fabric recycling initiative that will take leftover materials from our production and repurpose them into new garments, ensuring that even the smallest scraps find a new life. We can’t wait to share more on that and other initiatives later in the year.

At Son of a Tailor, we’re committed to quality, sustainability, and innovation. Stay tuned as we continue shaping the future of fashion.